Bending the rules of wood lamination

Fall 2013

I wanted to figure out how to make a fully "cereal bowl" concave deck using a vacuum press, and build a topmount deck that was ergonomic, rugged, and looked great.

Without a massive hydraulic press, making wood laminates bend in two directions is challenging if not impossible. In a vacuum press, where pressure is limited, it can only be done very subtly. Rocker/concave boards take two mild bends in perpendicular directions, but nothing as aggressive as I needed to get a bowl concave with a micro-dropped platform.

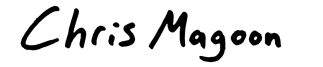

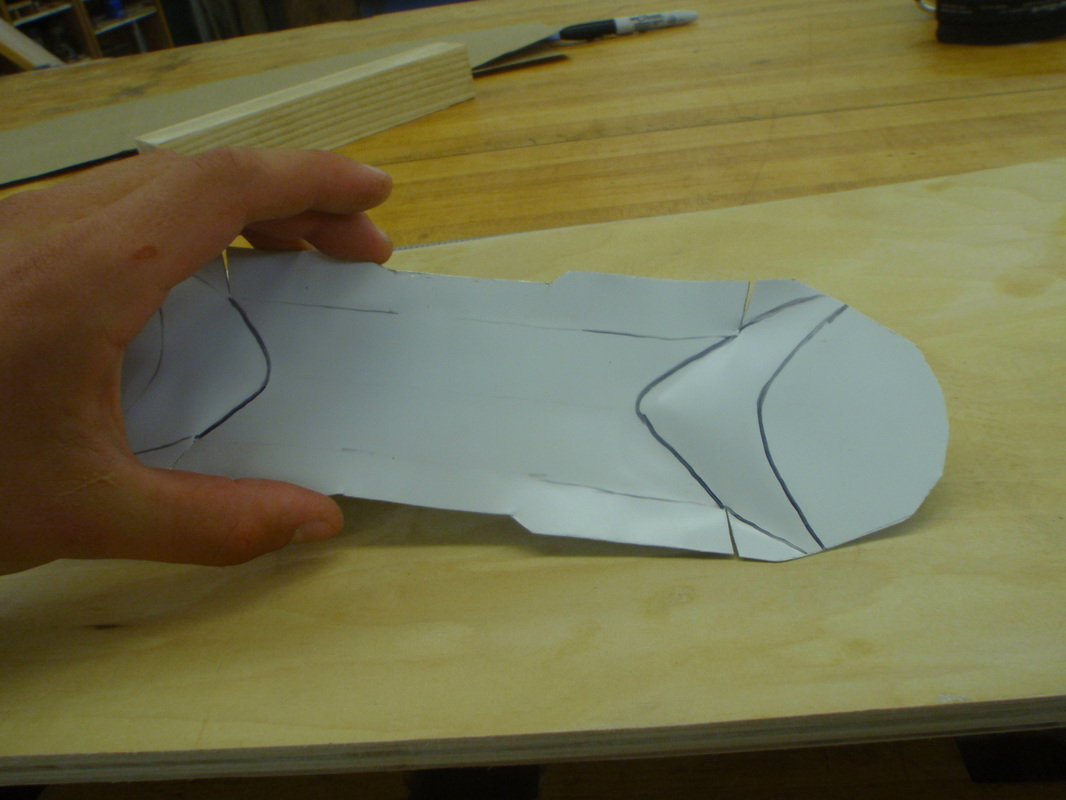

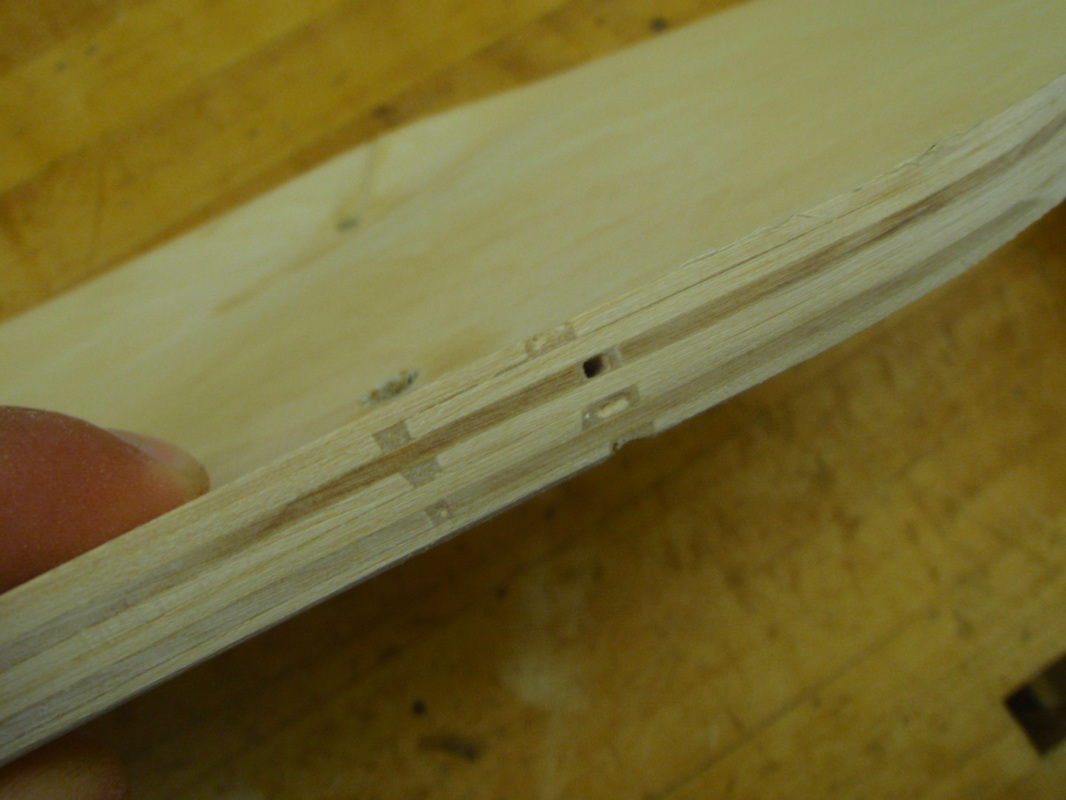

I started by folding paper to figure out how to make the bends I needed, then moved to sheet metal, and finally a Google Sketchup model. The plan was to create small relief cuts at the edges of the standing platform to allow the wood to curve inwards, forming the bowl concave I was after. To keep the cut joint strong, I staggered the cuts so they essentially wove together in a finger joint.

I started by folding paper to figure out how to make the bends I needed, then moved to sheet metal, and finally a Google Sketchup model. The plan was to create small relief cuts at the edges of the standing platform to allow the wood to curve inwards, forming the bowl concave I was after. To keep the cut joint strong, I staggered the cuts so they essentially wove together in a finger joint.

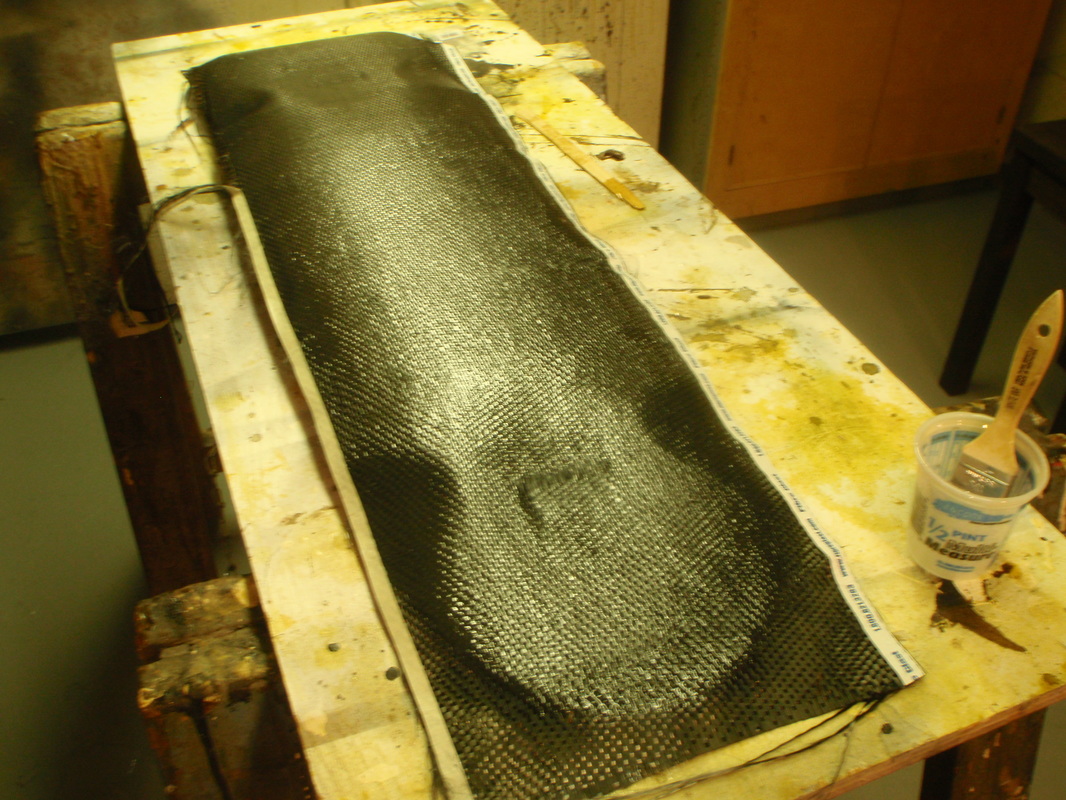

In addition to joining the relief cuts, I added a layer of carbon fiber to the base of the board and 2 layers of fiberglass to the top. This sandwich made the deck rock solid, with excellent torsional rigidity for freeride and downhill. I also added nylon guards to the nose and tail of the board to keep the deck from getting smashed up.