Twin Tip Nordic skisFall 2014

|

Skills

Composite lamination Wood lamination Vacuum bagging |

|

|

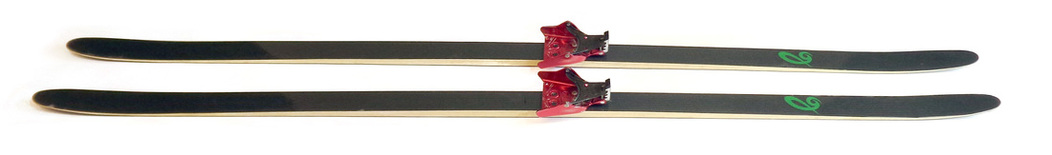

After years of making custom longbaords, I wanted to add a pair of custom skis to my quiver. I wanted a pair of skis I couldn't buy: twin tip nordic skis with early-rise tips and a very low camber and mild flex. Essentially, a pair of alpine park skis...but for nordic.

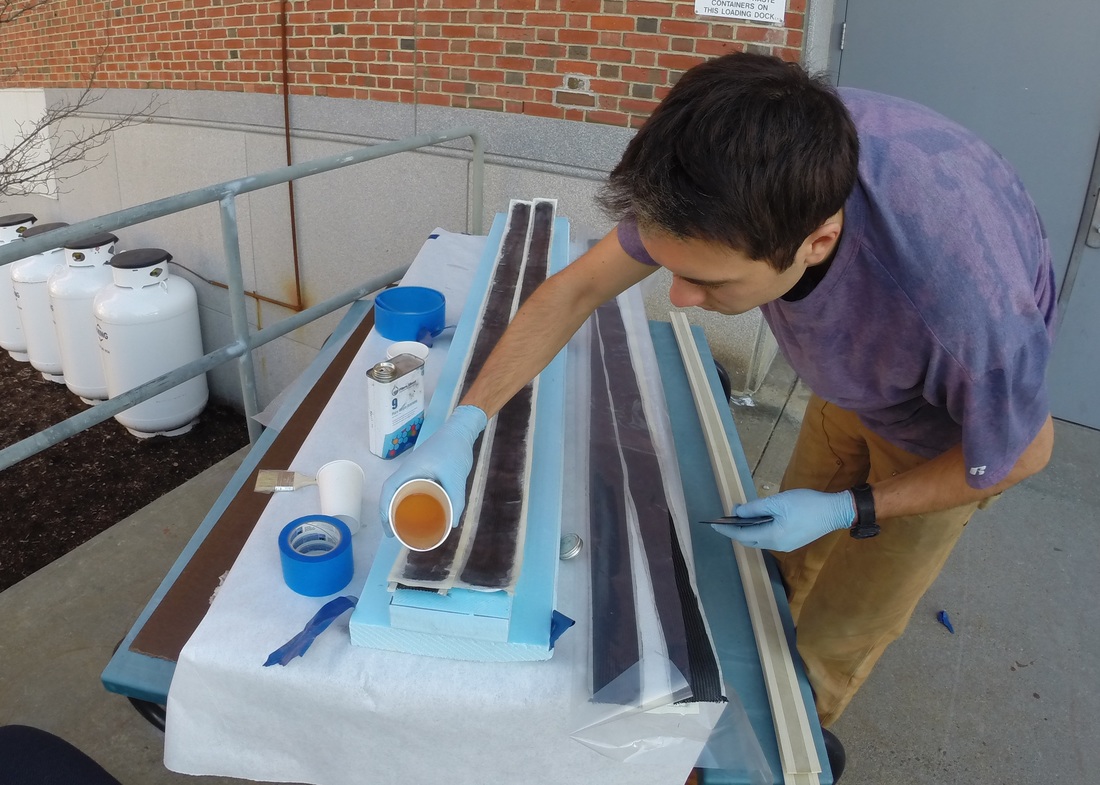

I designed the profile of the skis in SolidWorks, basing the camber and sidecut off of my favorite pair of modified skis. I cut a form out of foam to use to vacuum press the skis just like I make longboards. I started by making poplar cores; the wood had to be cut and laminated together, then planed to give it the correct taper. I used sintered UHMWPE sheet for the base and a polyethelyene topsheet. I tested different composite layups, using biaxial carbon, biaxial fiberglass, and graided carbon sleeve. The braided carbon sleeve, with fibers running at 45 degrees to the ski, gave the best torsional flex combined with fiberglass for the rest of the the reinforcement.

I designed the profile of the skis in SolidWorks, basing the camber and sidecut off of my favorite pair of modified skis. I cut a form out of foam to use to vacuum press the skis just like I make longboards. I started by making poplar cores; the wood had to be cut and laminated together, then planed to give it the correct taper. I used sintered UHMWPE sheet for the base and a polyethelyene topsheet. I tested different composite layups, using biaxial carbon, biaxial fiberglass, and graided carbon sleeve. The braided carbon sleeve, with fibers running at 45 degrees to the ski, gave the best torsional flex combined with fiberglass for the rest of the the reinforcement.

I did the layup process outside for the best ventilation I could find. Once the skis were layed up, I brought them into the boiler room to cure. At around 130 F, this is a good temperature for curing epoxy. An elevated temperature cure is also critical when gluing to plastics (the base and topsheet) that don't bond well at room temperature. After 24 hours of cure time, I pulled the skis out and cut and sanded them to shape, with a final coat of epoxy on the exposed sides of the wood core.